Our coatings offer protection for metallic interconnects and provide the stability, reliability, and performance needed for your demanding applications.

This coating technology has been proven over thousands of hours of testing and over 10,000 coated parts have already been delivered to the field. This success can be attributed to the high-performance, service, and quality standards we have established. These standards enable us to produce the best interconnect coatings on the market with the highest level of customer service.

Protective coatings for metallic Balance of Plant (BoP) components.

Our coatings are designed for high-temperature corrosion protection for steel and superalloy components.

The ChromLok™ System

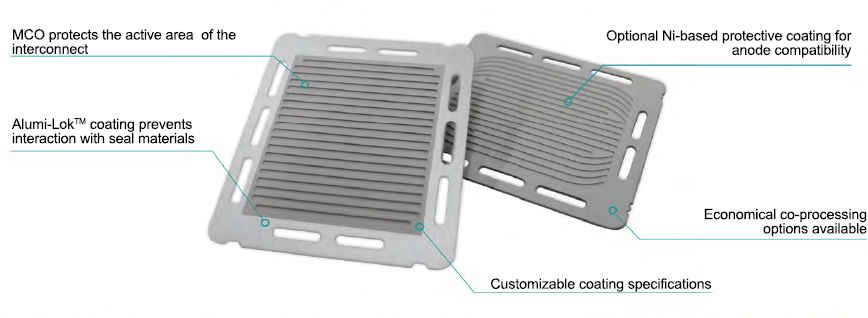

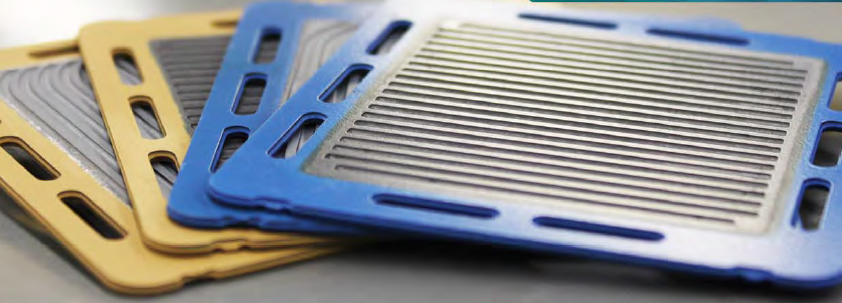

The ChromLok™ System is designed to enhance alloy stability and it prevents chromium volatilization. It provides metallic components used in solid-oxide fuel cell systems with the high-temperature protection they need. It includes a range of complementary oxide coatings that prevent the release of detrimental chromium species from stainless steels during high-temperature operation.

Coatings include manganese cobaltite (MCO) coating, which combines excellent protection with low resistance, ideal for the cathode active area where electrical conductivity is critical. Additional coatings include non-active, insulating coatings compatible with common seal materials and a Ni-based anode side coating.

The AlumiLok™ System

The Alumi-Lok™ protects metallic components from coking, corrosion, and degradation in oxidizing environments. It offers an aluminization coating to protect the non-active area of the interconnects and critical Balance of Plant parts from the effects of high-temperature corrosion. This coating is designed to be processed at the same time as the other coatings on the interconnect, ensuring an economical solution is maintained.

Catalyst Coatings

Our materials specialists collaboratively design custom aerosol, dip, and wash-coated catalyst coatings for catalysts synthesized by HPS or our partners.

We have decades of experience coating catalysts onto metal and ceramic substrates, monoliths, tablets, plates, and foams.

HeatPath can assist through all phases of product launch.

Prototype Manufacturing

- Interconnect coatings to your specifications

- Prototype batches for process validation & stack test

- Parts are coated by our dedicated coating team

Manufacturing Scale-Up

- Contract coating batches for intermediate quantities

- Early-stage manufacturing to your specifications using our established production line

- Significant cost reductions for volume orders available

High Volume Manufacturing

- License product and transfer technology

- Easily incorporate our technology into your own manufacturing system

- Materials supply agreements to ensure all your needs are met